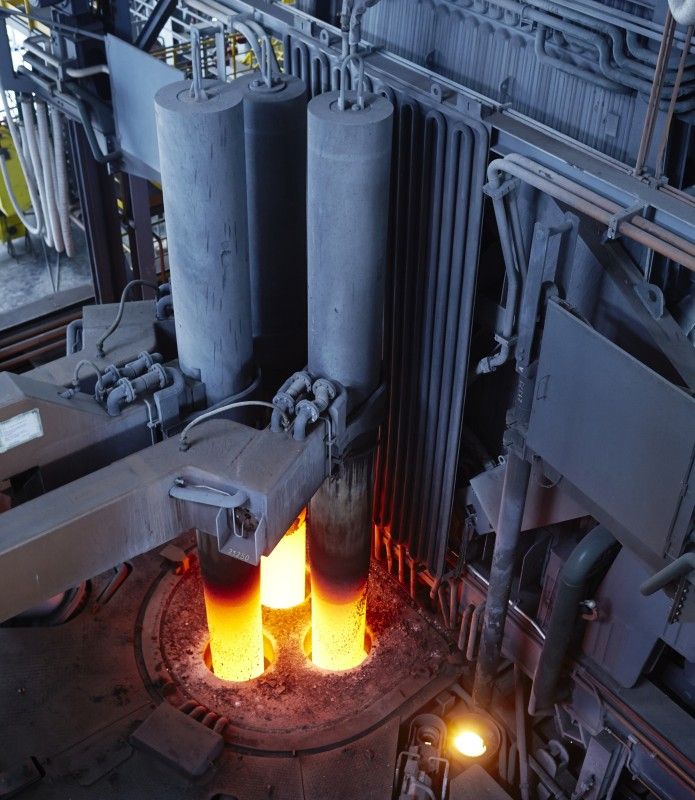

Lengthwise Graphitization Process (LWG): Efficient Graphite Transformation

We provide advanced solutions for electrode and nipple production using LWG (Lengthwise Graphitization Process) furnaces. Designed for high efficiency and product consistency, LWG technology enables low energy consumption, minimal raw material waste, and continuous automated operation. This helps manufacturers boost output, reduce costs, and stay ahead in carbon production.

Our Approach

We deliver complete solutions for the implementation of LWG (Lengthwise Graphitization Process) furnaces enabling efficient, high-quality production of electrodes and nipples. Our expertise spans across plant design, system integration, and process optimization to ensure maximum performance and sustainability.

By leveraging the advantages of LWG technology such as low energy use, reduced maintenance, and high product quality we help manufacturers future-proof their production with efficient and scalable operations.

Key Advantages of LWG Technology

- Consistent high product quality

- Low maintenance costs

- Optimized furnace cooling

- Reduced use of refractories

- Low operational labor costs thanks to a high degree of automation

- Low energy consumption

- Reduced consumption of insulating materials

- Metallurgical coke

- Lignite coke

- High environmental and safety compliance